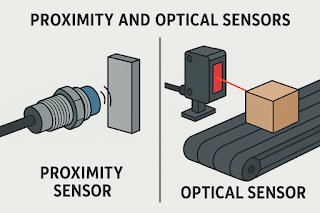

Proximity and Optical Sensors: Types, Working Principle, and Applications

In the world of industrial automation and smart systems, sensors are essential components. Among these, proximity sensors and optical sensors stand out as key devices for detecting the presence or position of objects without physical contact. This article explores their types, working principles, and main industrial applications.

1. Proximity Sensors

Definition

A proximity sensor detects the presence of an object when it comes within a certain range, without any direct contact. These sensors are widely used in automatic systems and industrial monitoring.

Types and Working Principles

A. Inductive Proximity Sensors

Application: Detect only metallic objects.

Working principle: They generate an electromagnetic field. When a metal object approaches, it disturbs this field, causing a change in the electrical signal.

B. Capacitive Proximity Sensors

Application: Detect both metallic and non-metallic objects (e.g. plastic, wood, liquids).

Working principle: They operate based on a change in capacitance when an object enters the electric field.

C. Magnetic Proximity Sensors

Application: Detect magnetic fields or magnets.

Working principle: Based on the Hall effect, they react to changes in a magnetic field.

Common Applications

Automated production lines.

Detecting the final position of moving parts.

Machine safety systems.

Automatic part counting.

2. Optical Sensors

Definition

An optical sensor detects the presence of an object or a change in light using visible or infrared radiation. It's ideal for longer-range detection and identifying non-metallic items.

Types and Working Principles

A. Through-Beam (Barrier) Sensors

Consist of a separate emitter and receiver.

When an object breaks the light beam, the sensor detects its presence.

B. Diffuse Reflection Sensors

Emitter and receiver are in the same unit.

Light reflects directly from the object back to the sensor.

C. Retro-Reflective Sensors

Emitter and receiver are together; a reflector is placed opposite.

The light beam is reflected back unless an object blocks it.

Common Applications

Sorting and packaging in food or pharmaceutical industries.

Detecting presence/absence of items on conveyors.

Fast counting systems.

Safety systems like light curtains.

Comparison Table

Feature Proximity Sensors Optical Sensors

Target Type Metallic or non-metallic Any visible object

Detection Range Short (a few cm) Longer (up to several meters)

Precision High at close distances Medium to high

Environments Harsh industrial conditions Versatile, lighter environments

and optical sensors are fundamental to modern automation, increasing accuracy and efficiency in control systems. The right sensor depends on the type of target, required distance, and operating environment.

.png)